info@venimed.com.tr

+90 (224) 364 07 20

Home Page / Production / Product Specifications

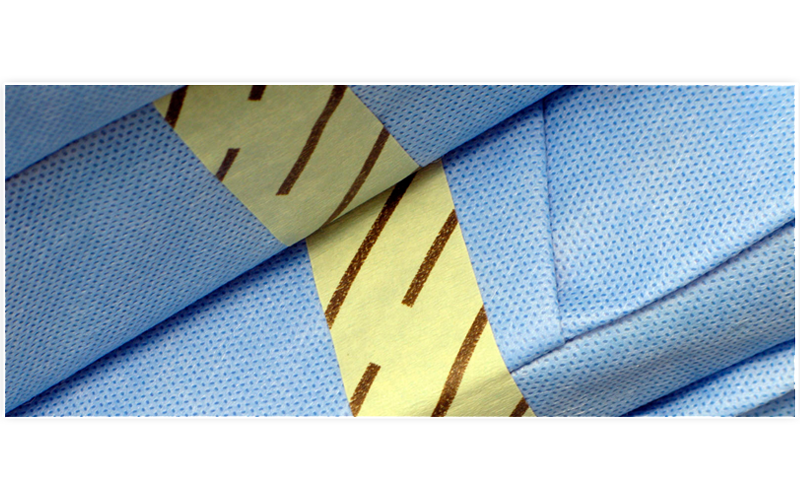

Our products are manufactured with the raw materials that are called as non-woven which are in conformity with the EN 13795, providing great convenience to the patient and user in terms of the comfort and health.

These fabrics have fluid absorption or repellency characteristics which are also breathable in concordance with the tapes manufactured for the purpose of medical use and the incision films which are skin friendly and prevent all kinds of liquid, blood and bacteria penetration by taking the operation field under protection during the surgical interventions.

High quality raw material supply from CE holding manufacturers is the basic principle in raw material supply chain.

The biocompatibility is provided by the Department of Pharmacology for the raw materials used in our products through;

Examining whether death-toxic occurs on the cell,

Examining whether they cause an allergic reaction,

Examining whether they cause a reaction on the skin, by applying the necessary tests. Therefore, it is determined that our raw materials will not cause any reaction since they contact with the skin.

The conformity of the EN 10993 quality standard’s requirements is controlled during the raw material supply and product quality is maintained in maximum level, in the first phase, by preferring the raw materials of the companies complying with this standard.

The production phase is completed in accordance with the instructions and procedures in conformity with the system’s requirements. In our facility, we have a clean room complying with the standards of Class 100.000

Our clean room has an infrastructure that will be able to make production in accordance with the conditions of Class 10.000 when necessary. Our clean room’s validation values had been evaluated as a result of the requirements of EN 14644-1 quality standard. Our products’ packaging phase and validation had been completed and is carried-out in a clean room at an optimum temperature with a packaging machine of which package temperature value had also been determined.

After the product’s packaging, the labeling is also carried-out in the clean room conditions and prepared by considering the graphics and symbols found in the EN 980 Medical Devices’ Labeling. Our products’ packaging material is in conformity with the EN 868-7 standard and provides the necessary conditions in terms of the ETO gas permeability.

In addition to our standard products, our production is in conformity with necessary instant changes that will be able to meet the customers’ customized requests. Folding process and guiding labels on surgical drapes provide an unique guide while laying on patient without breaking the sterilization and thus, isolate from the infections that will be able to reach to the operation fields from the environment. Our disposable surgical gowns ensures a sufficient protection from microorganism , infection originated from the patient and also offers comfort to the user by means of its air-permeable texture.

When our products are compared with the multiple-use textile drapes, these characteristics reduce the infection risk to minimum for the patient, providing safety and comfort for the user. Moreover, when the spent energy, manpower and infection risk to bring the textile drapes to reusable condition are taken into consideration, the drapes and gowns manufactured by the disposable fabrics are more cost effective.